A University of Nevada, Reno Mechanical Engineering Capstone Project In Cooperation with Lawrence Livermore National Laboratory

Division By Zero

Initial Design Concepts

Each team member created a unique design concept that met the requirements of the project. The concepts were evaluated for selection as the final design by the team based on engineering analyses of the designs, functional criteria, and market research conducted among other Capstone students. Brandon's concept was ultimately selected as the final design for the prototype.

Brandon |  Uriah |  Mike |

|---|---|---|

Chris |  Alex |

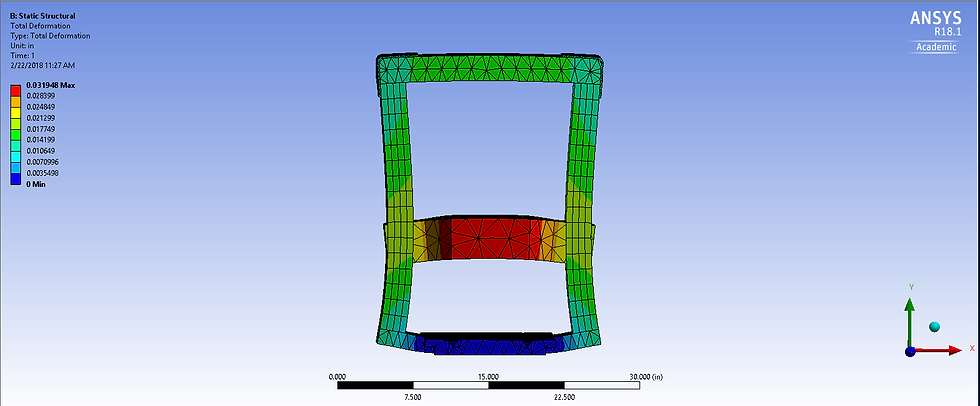

Proof of Concept

The selected design was modeled using SolidWorks and evaluated using finite element analysis in both SolidWorks and ANSYS. The model was simplified, as shown on the left, to enable SolidWorks and ANSYS simulations to run in a reasonable amount of time. The required load of 15,000 lb was modeled using multiple heights of the crosshead and multiple offsets from center to evaluate the integrity of the load frame and ensure that failure would not occur under any expected usage conditions. Failure during these analyses was defined as induced maximum stress at any point on the load frame exceeding the yield stress of that particular component. Metrics measured during the simulations included maximum deformation, von Mises stresses, and principle stresses.